Piller tackles key challenges of Australia’s changing power landscape

Read More

25 Years of Service

Read More

Annual Report & Accounts 2023

Read More

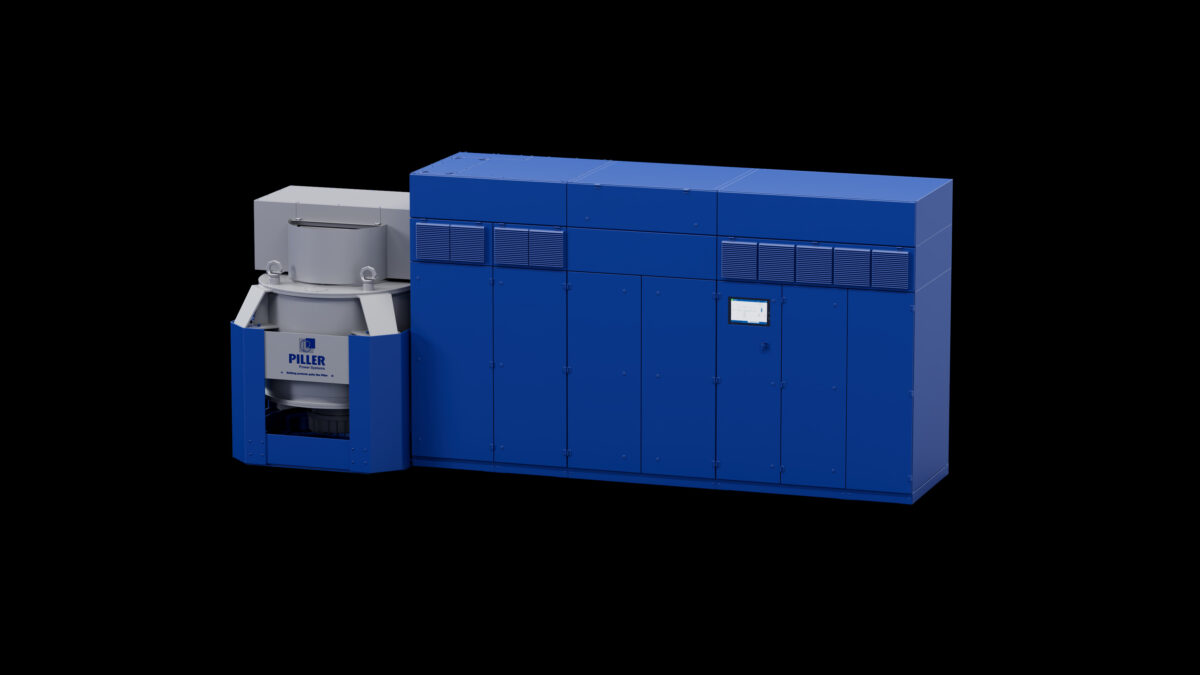

Piller UPS Chosen by US Semiconductor Manufacture

Read More

See us at Data Centre World London

Read More

Energy Transition and Grid Constraints

Read More