UNIBLOCK™ UPS up to 50MW

The UNIBLOCK™ is a key contributor in providing seamless power to your business systems and processes. Providing independence from utility power and disturbances on the supply network.

UNIBLOCK™ simply provides confidence in delivering business on schedule day after day, year after year. The UNIBLOCK™ gives high efficiency and performance with minimum components.

UNIBLOCK™ UB-V Series Electrically Coupled UPS for Hyperscale Data Centres

UPS from 1MW up to 50MW

The new UB-V series UPS platform is designed for the typical large scale data centre and combines cost effective ownership with high reliability, efficiency and power density.

The UB-V Series UPS is Piller’s latest generation of UPS. A completely new electronics platform affords even higher reliability through advanced self-diagnostics and a revised internal architecture employing a unique real-time Ethernet communication protocol known as PillerLINK™. A patented ring topology provides redundancy between electronic boards powered by redundant power supplies that are fed from redundant sources.

UNIBLOCK™ UB-V Series Electrically Coupled UPS for Industrial & Other Applications

Technological advances in virtually every field of human endeavour are bringing unprecedented demands for clean, uninterrupted power and with it, the need for ever more dependable, powerful and flexible UPS solutions.

In every industrial application, new technology deployment poses corresponding UPS challenges and issues associated with load changes, harmonic isolation, ambient conditions and power wastage are more potentially damaging than ever. Piller’s UB-V Series, built on the renowned German reliability of UNIBLOCK™, represents the most flexible and reliable electrically coupled rotary UPS available today.

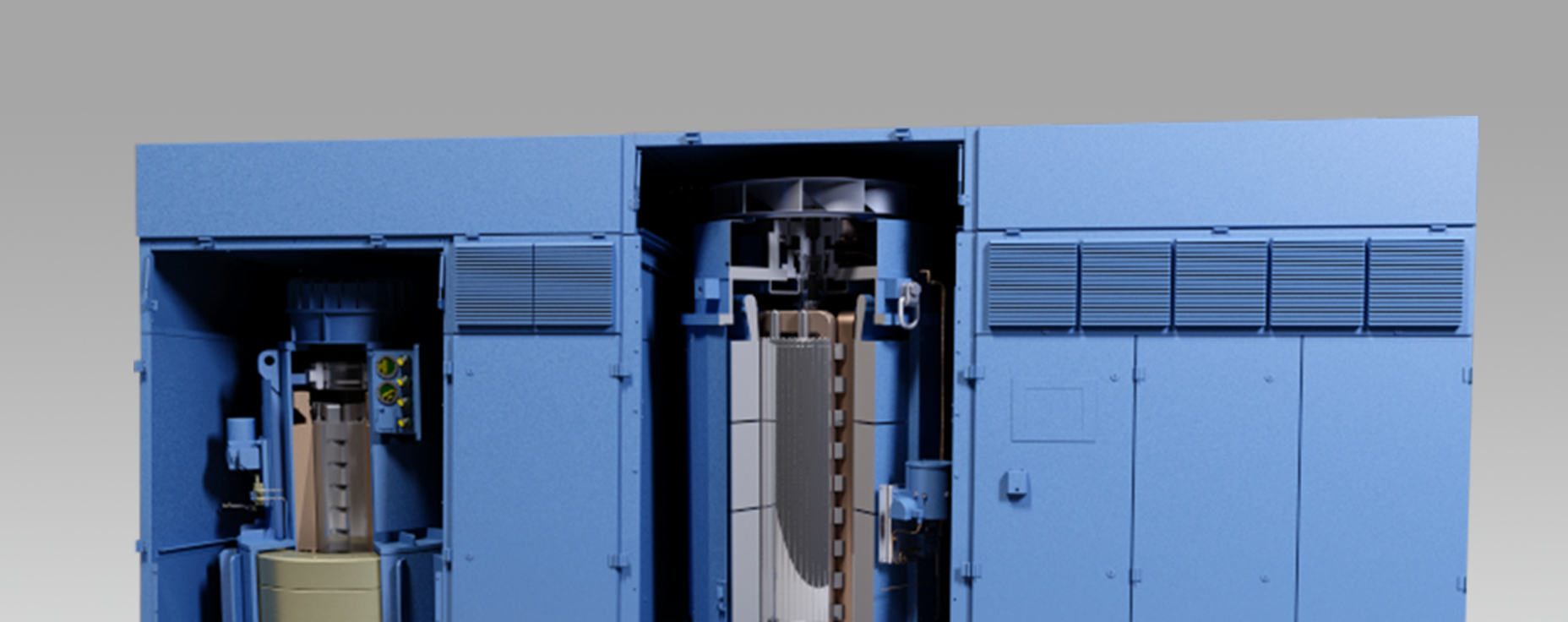

UNIBLOCK™ UBT+

Rotary UPS

The Piller UNIBLOCK™ UBT+ is a UPS system with state-of-the-art technology. The unique design with versatile options makes the UBT+ perfectly suited for existing or new installations.

The UBT+ is giving the highest efficiency and performance with minimum components and combines the benefits of all different power supply configurations for short term or long term bridging, with standby generation or with cogeneration. The UBT+ can be used in low and medium voltage applications, cooling can be by air or chilled water, ride through storage can be batteries or flywheel.

UNIBLOCK™ UBTD+

Rotary Diesel UPS from 500kW up to 40MW

Piller’s rotary Diesel UPS systems of the patented UNIBLOCK™ type represent the most efficient and reliable power supply combination for critical applications.

The design flexibility of the UBTD+ is unique for a UPS system, it can be used to address low and medium voltage applications, cooling can be by air or chilled water, critical and emergency supplies can be isolated or combined in a single distribution system. Diesel start delay can be varied from seconds to minutes and multiple engine designs can be accommodated.

UNIBLOCK™ Options

The UNIBLOCK™ rotary UPS range is flexible in application – there are a number of options available to suits clients specific requirements.

As an alternative, the UNIBLOCK™ system is also available as a high-performance and economical container unit. All components necessary for operation are integrated and the system is immediately ready for operation after coupling to the AC supply system. This eliminates planning costs as well as the costs of integration into the building structure.

The UNIBLOCK™ UPS can be provided with its own heat exchanger directly connected to the building’s chilled water supply. An integrated cooling unit provides the UPS with its own climate. The UPS can be operated in small rooms, in aggressive environments or in areas where quiet operation is required. Without the need for external forced cooling, complex plant room airflow studies can be eliminated, space can be saved and maintenance routines simplified.

Latest news

Let’s talk behind-the-meter (island) power for AI Data Centres.

Read MoreDownloads

-

UB-V Series Industrial Sector Flyer 50Hz

-

UB-V Series Industrial Sector Flyer 60Hz

-

UB-V Series Industrial & Healthcare Brochure

-

UNIBLOCK™ UBT+ Brochure

-

UNIBLOCK™ UBTD+ Brochure

Related products

UB-V Series for Data Centres

Introducing Piller’s new high-performance UB-V ELECTRICALLY COUPLED UPS series for the conditioned power protection needs of cloud hyperscale, wholesale colocation and large enterprise deployments.

UB-V Series for Industrial & Other Sectors

Meeting today’s industrial and commercial power protection challenges. Technological advances in virtually every field of human endeavour are bringing unprecedented demands for clean, uninterrupted power and with it, the need for ever more dependable, powerful and flexible UPS solutions.

CPM – Critical Power Modules with Flywheel 225kW up to 2.4MW

Meeting today’s industrial and commercial power protection challenges. Technological advances in virtually every field of human endeavour are bringing unprecedented demands for clean, uninterrupted power and with it, the need for ever more dependable, powerful and flexible UPS solutions.